Cattle slaughter lines

Couédic Madoré has developed its expertise over 35 years in the design, manufacture and installation of cattle slaughter lines. It relies on its wide range of specialized materials to meet to the specific needs of each client.

Our know-how is expressed by taking into account, from the conception of the constraints related to the hygiene, the safety, the ergonomics and the maintainability of the materials.

Advantages

- Customized solutions

- Lines from 5 to 80 cattle/hour

- Integration of constraints related to the agro food industry

- Ergonomic design of workstations

- All our materials comply with the European Machinery Directive

Our range of stunning box, allows the treating of every size of animals, from calves to competitive bulls while meeting the animal’s welfare requirements (European regulation 1009/2009).

Our stunning boxes allow the head to be perfectly aligned for safe use for the personnel.

- Traditional box with an internal or external chin lifter

- Secure box named “Securibox”

At the exit of the box, a cradle or a belt allows slinging of the beef. The robust and hygienic design of these materials is designed to facilitate the hanging of the animal.

For more safety for the personnel, we have developed an electrical stimulation system that paralyzes the cattle during slinging.

The setting up onto the rail is realized using a double chain elevator or a bleeding bar. These materials, are large enough in size, even for large cattle, are equipped with the necessary safety, allowing for the operators to work safely.

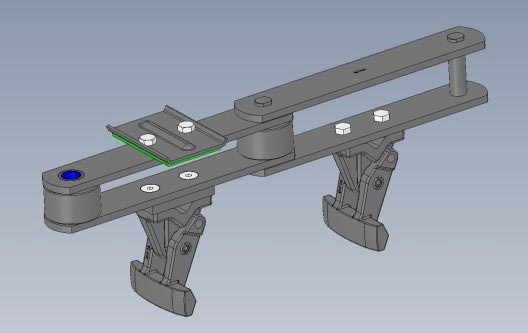

Our bleeding network, is composed of 2 profiles, these traps the trolley and avoids any risk of falling.

Bleeding is an operation that causes reflex movements of the cattle. For a safely working of the operator, we have developed materials to immobilize the legs of the animal during the incision. For mixed lines, these materials are mounted on pneumatic cylinders for the seizing of the legs. Reducing the difficulties for the operator that carries out the bleeding.

The troughs are designed with the aim of cleanability, to allow the optimum collection of blood, both quantity and quality.

For a better tenderness of the meat and for accelerated bleeding and to avoid the dripping along the dressing line, an electric stimulation can be operated on the bleeding rail.

The cattle transfer from the slings to the dressing trolleys is a delicate operation that requires precision from the operator and power of the equipment.

For the fixed station transfer, we are able to suggest either pneumatic cylinders largely dimensioned, or electric or hydraulic hoists. In any case, the control provided allows the precise control of stopping of the transfer hook for a fast operation and the safety of the operator.

- Pneumatic transfer

- Electric hoist transfer

- Hydraulic hoist transfer

- Double hydraulic hoist transfer

For high, continuous throughput, our process includes platforms and materials which reduce, as much as possible, the efforts of the operators.

Fixed or elevating platforms are designed and manufactured to achieve better work quality on the carcass, improves the operators comfort and allows for more efficient productivity.

Our expert knowledge of how the operations work, allow for better dialogue with our customers during the development of projects and allow us to design each work station to the customer’s needs.

The design of each platform integrates hygiene, safety and ease of maintenance, standards acquired by our design office in more than 30 years of dialogue with cleaning, maintenance services and control organisations.

- Height fixed platforms

- Elevating platforms

- Elevating platforms with frontal advance

- Specific platforms for the removal of udders

- Specific platforms of evisceration

- Specific platforms of splitting

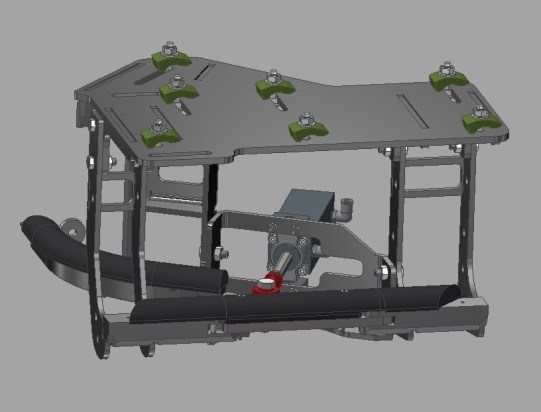

The hide-puller is a machine that requires immediate power, acceleration, precision and flexibility.

The hide puller is driven by hydraulic energy. Working from the top to the bottom, allowing a hygienic hide of the animals including the hide of the head if the height of the chain allows it.

The tetanising arm sends an electric current to the back muscles of the carcass to sufficiently rigidities the muscles to allow full power of the device.

A load reliever fixed in the frame, encircles the butts of the cattle. This avoids the transmission of the traction efforts to the hooks and consequently, the risks of rupture. Our materials can be equipped with sanitation boxes for the tetanisation arm and reliever.

The lateral platforms have been the subject of a study of ergonomics, to provide the operator with a good working position, comfort and optimum safety during the dehiding.

- Assistance drum

- DHB-100 de-hider for calves

- DHB-200 de-hider for cattle

- DHBI-400 de-hider for cattle, high throughput

- Loads relievers

Considering the weight of the heads, the cutting, working and hanging stations on the offal conveyor, must be designed to minimize the work load (lifting and moving) for the operator.

Many options are available and our sales engineers will advise the best adapted solutions according to the environment of the station.

An adapted station will allow the operator to work more efficiently and produce better quality work.

The operations of abdominal and thoracic evisceration of cattle are delicate. The risks of contamination to the carcass are considerable.

The masses to be handled by the operator are very important.

An ergonomic study of these stations is imperative to advise the correct installation, enabling the operation to be carried out in a hygienic way and without effort for the operator.

The removal of the bellies and red offal will be studied and adapted for each individual installation.

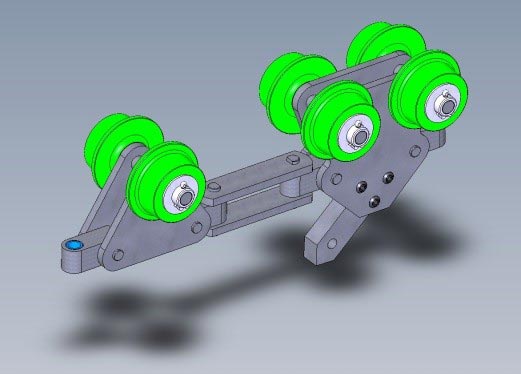

The loads carried by the chain conveyor need to be transported smoothly to the slaughter line. Conventional mechanical chains require lubrication to operate in a normal and sustainable way. Veterinary constraints no longer allow regular greasing of the chains. This results in a fast degradation of these and accelerated replacements.

As a chain manufacturer, we started working on this topic more than 20 years. Our R&D department, in collaboration with the maintenance engineers of our customers, have developed a range of chain (Autolub) that does not require any greasing.

The heat, surface treatments and the specific rings used, allow our chains to resist wear and oxidation, despite the very aggressive conditions of use during the production or cleaning phases.

Unlike the big manufacturers, who work primarily for automakers, we manufacture more than 80% of our chains for food related applications, with its constraints. (Ambient humidity, corrosive cleaning products).

The material which the channels to cover the slaughter chain and many co-products, troughs and gut room tables, which need to be worked on. May seem very basic, however, requires specific attention during their design and manufacture. They must be easily washable and have no retention zone (Inaccessible fold to washing, non-continuous weld)

Our designs are based on our long experience in the slaughterhouses industry, integrates cleanability from the design, and our quality department ensures strict control over the state of welds before shipping materials.

Products such as legs, hides, suet, bellies can be conveyed by belt.

For these materials too, the cleanability is a key point, whether in the frame or the conveyor belt. In addition to the hygienic design of our belts, we incorporate washing ramps for continuous cleaning of the belts.

Slaughter halls are often overloaded areas. We take special care to reserve access for maintenance and design our machines to limit the intervention time of technicians.

These conveyors collect offal along the slaughter line for inspection. They can also be used for cooling.

Our aerial conveyors for the offal transport are completely in stainless steel and are perfectly accessible for cleaning. Moreover, their opening structure allows them to move circulate neat operators without generating risk.

Pneumatic transfer systems can transport products over distances up to 100m.

We use two different processes:

The pneumatic cannon is used for fluid products such as: hot fats and stercoral matter. Our cannons, considered as pressurized equipment, are subjected to tough tests with recordings for validating their conformity. They are completely in stainless steel, as well as the pipes and the decompression cyclones.

The other method is the aspiration which allows transporting non-liquid products such as: heads, legs, hides (pipes up to diameter 350 mm). This method allows several points of collection for a same aspiration.

The drain elements, pipes and removal airlock of products are completely made in stainless steel.

Storage areas of carcasses after slaughtering are often overloaded and although the equipment may appear basic, it must be carefully designed, manufactured and installed with care.

The support frame, must of course, takes into consideration the carcasses loads, but must also be calculated to avoid bending, that would affect the proper functioning of switches.

We calculate and manufacture our frames with dedicated software that allow optimizing our supporting structure (CM66 calculation rules and Eurocode).

We offer several types of networks: round bar network and twin track rail for an adaptation of our customers’ installations.

For each kind of network, we offer a complete range of accessories: Hooks, manual or pneumatic switches, introducers, etc.

For several years, we have offered a «plastic» rail (patented) allowing a significant reduction of efforts and rolling noises when moving loads.

- Round bar network in galvanized steel

- Round bar network in plastic

- Round bar network in stainless steel

- Round bar network in aluminium

- Twin track rail in galvanized steel

- Twin track rail in stainless steel

The loads carried by the chain conveyor need to be transported smoothly to the slaughter line. Conventional mechanical chains require lubrication to operate in a normal and sustainable way. Veterinary constraints no longer allow regular greasing of the chains. This results in a fast degradation of these and accelerated replacements.

As a chain manufacturer, we started working on this topic more than 20 years. Our R&D department, in collaboration with the maintenance engineers of our customers, have developed a range of chain (Autolub) that does not require any greasing.

The heat, surface treatments and the specific rings used, allow our chains to resist wear and oxidation, despite the very aggressive conditions of use during the production or cleaning phases.

Unlike the big manufacturers, who work primarily for automakers, we manufacture more than 80% of our chains for food related applications, with its constraints. (Ambient humidity, corrosive cleaning products).

To proceed with the quartering of cattle, we suggest different materials to allow for different throughputs encountered by our customers.

The process of quartering can consist of a pneumatic levelling arm, a combination of chain lifts or even conveyors. Always allowing consideration of the ergonomics of the workstations and the maintainability of the equipment.

We also suggest using quartering saws (Freund materials of which we are the exclusive resellers on the French territory) and the adapted sterilizers, which allows for an excellent hygienic quality of the cut throughout the day.

Our range of loading arms allows us to suggest affective and safe solutions for the transfer of carcasses, quarters, Christmas trees and even for the setting in hammock in the trucks of half-cattle.

All our arms are hydraulic and conform to the regulations for the lifting.

To facilitate the grasping of loads, we can equip our arms with hydraulic tongs adapted to pigs or beef.