Pigs slaughter lines

We have been involved with pig’ slaughterers for more than 35 years. We have developed our know-how and the materials to best meet their new challenges. The productivity of a tool is related to the quality of the equipment involved: no weak link can be tolerated.

Also, all our equipment is designed in collaboration with the maintenance departments and we have integrated the principles of hygiene, safety and ergonomics.

Advantages

- Customized solutions

- Lines from 15 to 900 pigs/hour

- Integration of constraints related to the agro food industry

- Ergonomic design of workstations

- All our materials comply with the European Machinery Directive

We offer a wide range of boxes and restrainers to meet the different needs in terms of throughputs and weight of animals.

A good anaesthesia being a key point for the quality of the meat. We bring particular attention to the material of electro-narcosis as to the material of contention.

The Freund anaesthesia boxes send a moderate current, that limits the risk of fractures and blood stains.

Our compression materials ensure a good presentation of the pig for the anaesthesia (head or head and heart), while respecting animal welfare (in accordance with the 1099/2009 regulations).

- Box for pigs

- Box for sows

- Mixed box

- Restrainer for manual anaesthesia

- Restrainer with automatic anaesthesia

- Restrainer with automatic anaesthesia high throughput

After an electrical anaesthesia, the pig should be bled as quickly as possible.

Our bleeding tables allow a good presentation of the pig to the operator and an excellent recovery of the blood.

For trocar bleeding, blood can be collected by batch in tanks or individually in blood bags.

The hygienic design of our tables allows easy cleaning of all surfaces.

At the end of the belt, the slinging is at a good height and without any risk for the operator.

External treatment of the pig carcass begins with scalding followed by mechanical dehairing. The mechanization of the scalding allows the control of its duration and the quality of the result.

If the process remains the sale, the materials used will have to be adapted to the throughputs. Our know-how will always offer the right solution from our wide range of materials.

We pay particular attention to the thermal insulation of scalding equipment and to the energy performance of our heating systems.

- Combine scalding-dehairing for small throughputs

- Scalding tank up to 150p/h

- Mechanized barrel tank up to 150p/h

- Scalding tunnel with hot water or steam

- Sequential dehairer with or without singeing up to 150p/h

- Dehairer in continuous U-Bar type

At the end of dehairing, a table or a belt allows the preparation of the nerves and for putting the finishing carcasses on a rail.

Systems for presenting the pigs on the belt and the specific study of the hanging station, with the supply of tinets or hooks can significantly limit the ergonomics of the workstations.

Despite the good results obtained by efficient scalding and dehairing, finishing of carcasses is most often necessary for good presentation.

To do this, we have developed a wide range of singers and brushers.

Our singers of 2, 4 or 6 columns, recommended in relation to the throughputs, are isolated and the consumption of gas, mastered, thanks to a management of the burning column by column.

Heat recovery can be associated with our singers.

A crown for burning of the heads can be added, this is in particular for sows.

Our singers can also be used for sanitizing carcasses before dressing

Our singers of 4 or 6 rollers ensure the perfect finishing of the carcasses after burning. Their design, orientated towards the simplification for the maintenance operations. This allows a reduced maintenance schedule and for easy replacement of the whips.

After the external finishing, the dressing operation of the internal parts of the carcass is very delicate. The sanitary level requires hygiene and dexterity on the part of the operators and the machines.

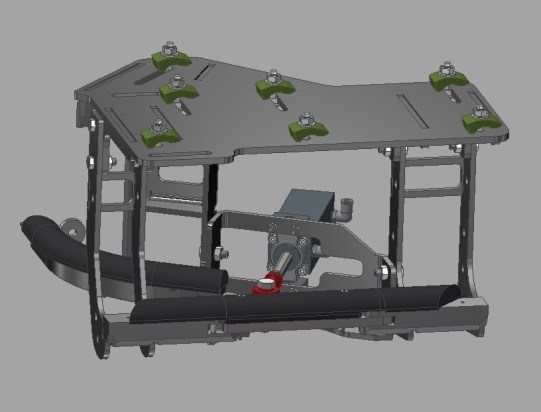

Work platforms

Fixed or elevating platforms are designed and manufactured to achieve better work quality on the carcass, improves the operators comfort and allows for more efficient productivity.

Our expert knowledge of how the operations work, allow for better dialogue with our customers during the development of projects and allow us to design each work station to the customer’s needs.

Each is equipped with the necessary hygiene equipment for the operations to be carried out.

The design of each platform integrates hygiene, safety and ease of maintenance, standards acquired by our design office in more than 30 years of dialogue with cleaning, maintenance services and control organisations.

- Fixed height platforms

- Elevating platforms

- Specific platforms for evisceration

To meet high throughputs and limit risks of TMS, we have designed a range of automatic machines to perform complex operations with precision and perfect repeatability.

Our range includes:

- Bunging robot

- Aitch bone and pre-opening robot

- Opening breast bone robot

- Heads disjointing robot

- Splitting machines with saws or knives

Our robots are fully manufactured in our workshops. Made completely in stainless steel, they are cleanable and do not require covering. The limited number of axis strictly necessary for the operations to be carried out makes it possible to have a reduced bulk and a dynamic that is impossible to obtain with 6 axis robots for the loads to be shipped.

The trajectories are based on 3D pictures of the carcasses allowing unequalled precision of work. We are able to propose a combination of robots according to the throughput needed.

Our splitting machines, with saws or knives, are suspended from the main frame, thus releasing the floor for easy cleaning of the area. Our knife box, perfectly balanced (patented system) ensures a regularity of the results of the cut and reduced maintenance.

The saw, entirely designed and manufactured by Couédic Madoré, ensures a very high throughput cutting, while maintaining an excellent level of hygiene of all the active parts of the saw.

The throughputs obtained go up to 500p/h per machine for knife models and up to 650p/h for saw models.

We also have in our range a knife splitting machine for calves.

In addition to the fully automatic machines, we have operator assisted devices. Among them, our leaf lard puller, which uses the dexterity of the operator for the precision of the gesture but it removes any effort, this one taken care off by a pneumatic cylinder.

We offer a range of 2 versions for this machine:

- 1 machine that can work on the 2 halves carcasses with 1 operator for throughput up to 300 p/h

- 1 set of 2 machines: a right shear and a left shear for throughput up to 700 p/h

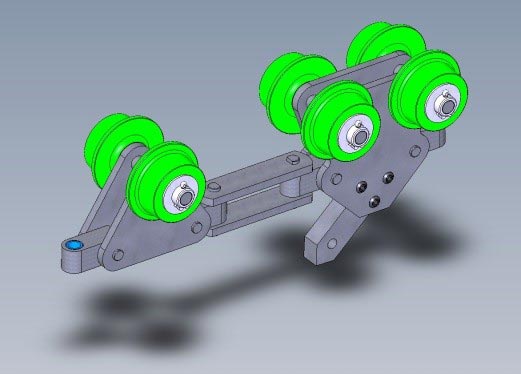

The loads carried by the chain conveyor need to be transported smoothly to the slaughter line. Conventional mechanical chains require lubrication to operate in a normal and sustainable way. Veterinary constraints no longer allow regular greasing of the chains. This results in a fast degradation of these and accelerated replacements.

As a chain manufacturer, we started working on this topic more than 20 years. Our R&D department, in collaboration with the maintenance engineers of our customers, have developed a range of chain (Autolub) that does not require any greasing.

The heat, surface treatments and the specific rings used, allow our chains to resist wear and oxidation, despite the very aggressive conditions of use during the production or cleaning phases.

Unlike the big manufacturers, who work primarily for automakers, we manufacture more than 80% of our chains for food related applications, with its constraints. (Ambient humidity, corrosive cleaning products).

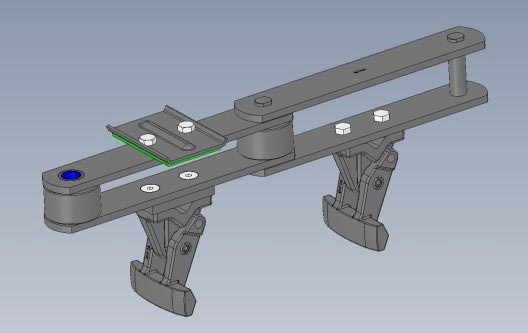

The collection of offal for presentation to the veterinary inspection on a pig slaughter line is generally carried out by 2 conveyors. Our inspection conveyors of red offal are designed to be able to adapt to very sinuous lines allowing direct hanging without risk for the operator. These conveyors are completely manufactured from stainless steel and are fully accessible for cleaning.

These same conveyors are used for the individual cooling of the offal, essential for a good bacteriological quality of the product.

For the white offal, the collection is done thanks to swing tray conveyors either lifted or suspended according to the slaughterhouse configurations. The wheels and sheaths of our conveyors are made of stainless steel to allow for cleaning requirements. Moreover, we have developed a chain, specially dedicated to this application, requiring no lubricating and supporting the contact of the cleaning products.

To allow continuous washing of swings and offal hooks, we have designed a range of disinfection cabins, some equipped with filtering and water recovery systems.

Treatment of white offal, highly sensitive, has to be done promptly after removal from the carcass.

Our white offal work lines provide fast cooling and continuous processing of the various components of the belly.

Flow and workstations are designed to allow to the operators to work in a hygienic and ergonomic way.

Pneumatic transfer systems can transport products over distances up to 100m.

We use two different processes:

The pneumatic cannon is used for fluid products such as: hot fats and stercoral matter. Our cannons, considered as pressurized equipment, are subjected to tough tests with recordings for validating their conformity. They are completely in stainless steel, as well as the pipes and the decompression cyclones.

The other method is the aspiration which allows transporting non-liquid products such as: heads, legs, hides (pipes up to diameter 350 mm). The method allows several points of collection for the aspiration.

The drain elements, pipes and removal airlock of products are completely made in stainless steel.

Storage areas of carcasses after slaughtering are often overloaded and although the equipment may appear basic, it must be carefully design, manufacture and installed with care.

The support frame, must of course, takes into consideration the carcass loads, but must also be calculated to avoid bending, that would affect the proper functionality of the switches.

We calculate and manufacture our frames with dedicated software that allows optimisation our supporting structure (CM66 calculation rules and Eurocode).

We offer several types of networks: round bar network and twin track rail for an adaptation of our customers’ installations.

For each kind of network, we supply a complete range of accessorizes: Hooks, manual or pneumatic switches, introducers, etc.

For several years, we offer a «plastic» rail (patented) allowing a significant reduction of effort required and rolling noises when moving loads.

- Round bar network in galvanized steel

- Round bar network in plastic

- Round bar network in aluminium

- Twin track rail in galvanized steel

- Round bar network in stainless steel

The loads carried by the chain conveyor need to be transported smoothly to the slaughter line. Conventional mechanical chains require lubrication to operate in a normal and sustainable way. Veterinary constraints no longer allow regular greasing of the chains. This results in a fast degradation of these and accelerated replacements.

As a chain manufacturer, we started working on this topic more than 20 years. Our R&D department, in collaboration with the maintenance engineers of our customers, have developed a range of chain (Autolub) that does not require any greasing.

The heat, surface treatments and the specific rings used, allow our chains to resist wear and oxidation, despite the very aggressive conditions of use during the production or cleaning phases.

Unlike the big manufacturers, who work primarily for automakers, we manufacture more than 80% of our chains for food related applications, with its constraints. (Ambient humidity, corrosive cleaning products).

Our range of loading arm allows us to suggest affective and safe solutions for the transfer of carcasses, quarters, Christmas trees and even for the setting in hammock in the trucks of half-cattle.

All our arms are hydraulic and conform to the regulations for lifting.

To facilitate the grasping of loads, we equip our arms with hydraulic tongs adapted to pigs or beef.