Our products

Couédic Madoré Equipement has developed a wide range of materials which are integrated into the processes. Our expertise in the various fields of the food industry offers the guarantee of the correct tooling for your requirements.

We integrate all manufacturing processes to achieve permanent quality and delivery times.

CME is member of EHEDG foundation created in 1989 for promoting the hygienic design of materials and installations in agro-food industry.

Advantages

- Custom manufacturing

- Controlled production and integrated manufacturing

- Integration of agro-food industry constraints

- Hygienic and ergonomic design

- All our materials comply with the European Machinery Directive

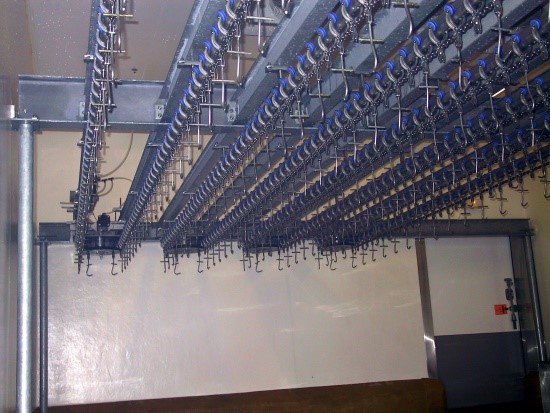

Couédic Madoré have different types of aerial networks in order to adapt to your existing installation and/or to take account of your various constraints (loads, aggressive environment, etc.):

- Round bar rail system 40/49, 50/60 or Plastilux

- Aluminium twin track rail system: Transuni, Biralux or Marcolux

- Stainless steel twin track rail system

- Heavy twin track rail system (for the important loads)

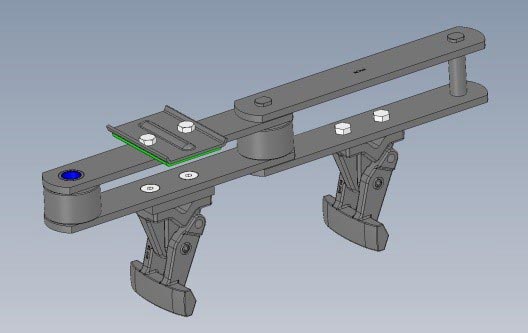

The loads carried by the chain conveyor need to be transported smoothly to the slaughter line. Conventional mechanical chains require lubrication to operate in a normal and sustainable way. Veterinary constraints no longer allow regular greasing of the chains. This results in a fast degradation of these and accelerated replacements.

As a chain manufacturer, we started working on this topic more than 20 years. Our R&D department, in collaboration with the maintenance engineers of our customers, have developed a range of chain (Autolub) that does not require any greasing.

Unlike the big manufacturers, who work primarily for automakers, we manufacture more than 80% of our chains for food related applications, with its constraints. (Ambient humidity, corrosive cleaning products.).

Couédic Madoré have several types of chains to suit different applications:

- Monoplaner or polyplaner chains

- Standard or Autolub chains

- AM2, AM3, AM5, AM250 AM250-4, CMR, Webb, models etc.

- We can manufacture chains according to a required model.

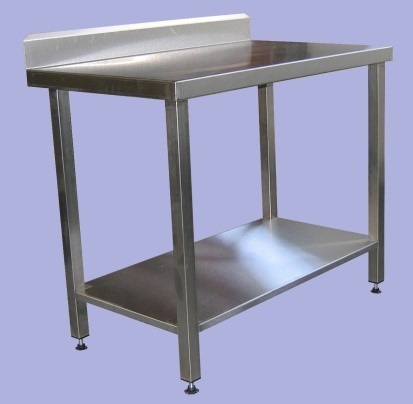

For more than 30 years we have been working to improving our materials.

Particularly, for every conveying system concerning naked products, for which hygienic and cleanliness are crucial.

Listening to the requirements of our customers (cleaning, maintenance, manufacturing) and taking into account the requirements of the EHEDG (European Hygienic Engineering and Design Group), of which we have been a member for many years. We have developed our products to make them references.

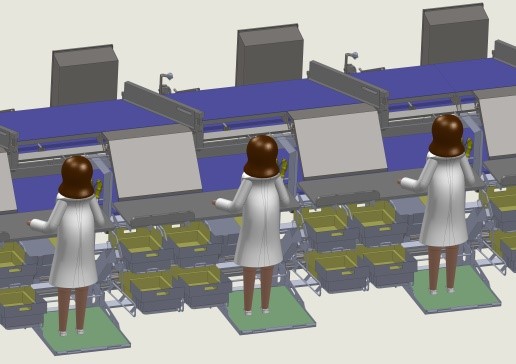

The correct design of work station is required for the quality of work performed, for the productivity and the comfort of the operator.

Our design work finely studies the tasks required by the operator and apply’s the principles of ergonomics.

Thus, the study of each station will allow the operator to have the correct tooling and hygienic materials on hand.

For us, a work line is not 1 time X stations but X times 1 station.

Our range of adaptable workstations for the customer’s needs, is very wide:

- Elevating platform, Manufactured from sheet metal.

- Elevating platform with frontal advance

- Elevating platform with waste water collecting tray

- Fixed platform height adjustable

- Working podium – manual height adjustment

- Standing station

- ….

- All stations are manufactured to the required specifications

Trays are containers widely used in slaughterhouses and cutting factories. They serve from meat storage to disposal of the most varied waste.

To meet all demands, we have developed a range of tippers and lift tipping devices for all types of trays and loads.

Depending on the applications, adaptations on the channels or other parts of machines may be required (please consult our sales representatives).

All our machines are designed for lifting loads, are in compliance with the lifting standards and the « Machine » directive. Operators can work safely, even with the heaviest loaded containers.

We also design a range of battery operated mobile tippers for working on several workstations.

As lifting devices are considered as potentially hazardous materials, we have been working with the CARSAT on these materials according to the INAVAP method (Informations Nécessaires AVant l’Achat pour la Prévention des risques professionnels = Necessary Information Before Purchasing for the Professional Prevention of Risks) Administration which recommends , from the design, to analysis the risks by integrating all the stages of the life of the material : manufacturing, cleaning and maintenance periods..

Our range includes among others:

- Tipper for cutting trays

- Tipper for Europe trays or equivalents

- Tipper for Jumbo trays or equivalents

- Lift tipping device for cutting trays

- Lift tipping device for Europe trays or equivalents

- Lift tipping device for Jumbo trays or equivalents

- All type of material according to specifications

Hygiene is the essential element in the agro-food industry and in particular in the slaughterhouses and cutting units, where the meat is bare.

To take on board these constraints, we have developed a wide range of cleaners and sterilizers for every type of tool and materials, from the simple knife sterilizer to the washer of trays with water recycling.

We are also aware of the need to limit water consumption, we integrated low consumption nozzles into our sprays equipment, that we have precisely positioned to clean the active areas of tools.

For cases where scraping is necessary, (for example hooks and gambrels) we have used ultrasonic blocks before disinfection phase.

Specific sterilizers are also on-board on our automatic machines: robots, splitting machine, and on materials as stimulating machine and supports for de hiding machine for example.

Materials suggested by Couédic Madoré are:

- Knives sterilizer or soaking saw

- Knives sterilizer or spraying saw

- Spraying washing cabin for hooks and carriers

- Ultrasonic washing cabin for hooks or gambrels

- Washing machine for trays high-throughput

- Sterilizer for automatic machines

- Sterilizer for stimulating machine and support for dehiding machine

- All type of material according to specifications

To limit the rolling tray flows in slaughterhouses and cutting units, more often than not could this can be inconvenient for the operation; we worked on 2 different air transport systems:

- Cannon blower is used for liquid product as hot fats and stomach content. Our cannons, considered as pressurised machines, are subjected to tests with records to validate their conformity. They are made completely from stainless steel, as well as the piping and decompression cyclones.

- The other suction method allows transporting non-liquid products as heads, paws, paunches, cold fats (piping until diameter 350mm). It allows several collection points for the same suction. Suction drains, piping and collecting SAS of products are completely made from stainless steel.

The carcasses transfer or carriers from the network of wharves to trucks must be done quickly to limit the opening of doors and the immobilization of vehicles.

Couédic Madoré Equipement has developed several models of hydraulic truck loading arms, fast and manageable, to meet the different needs of industrialists:

- Hydraulic arm for loads up to 300 kg

- Hydraulic shear arm dedicated for loading pigs on gambrels

- Hydraulic shear arm dedicated for loading of beef quarters

- Hydraulic loading arm of beef halves with Wi-fi controls

For the placing in caddies, we also have hydraulic arms to lower loads that can be either completely hanging or placed on the ground on base and movable depending on the place of use.

All our arms meet the requirements of the « Machine » directive and are tested with loads in accordance with the standard on the lifting materials equipment.

We supply a full range of accessories and rolling equipment needed for the operation of the slaughterhouses and cuttings.

The majority of the equipment is manufactured in our workshops, with a design for quality and is designed to resist specific constraints of the agro-food industry

- Trolleys

Service trolleys

Platform trolleys

5 floors trolleys

Pastry scales (rack storage)

- Tanks

Europe tanks

Rendering bins

Rolls-bins

- Overhead handling trolleys

Round bar trolleys 40/49 and 50/60

Twin track rail trolleys

Heavy twin track rail trolleys

Stainless steel hooks Ø14, 16, 18 & 20

Straight gambrels, “V”-shaped, aluminium or stainless steel

Bleeding slings for pigs

Bleeding slings for cattle

Hams, loins or sheep carriers

Possibility to manufacture according to the model or on specifications

In direct contact with the design office and the manufacturing department, the « spare parts » service will answer you as soon as possible to provide you with the standard or specific equipment necessary for the proper operation of your installation.

Our comprehensive data files, with more than 30 years of history, will allow them to respond precisely, even on materials.

- Original spare parts

- Motoreducers, cylinders…

- Beaters according to dehairer model

- Whips according to brusher model

Couédic Madoré Equipement is the exclusive dealer of Freund company (German manufacturer of shears and saws) on the French territory and we can supply, as such, a completely range of cutting tools for slaughtering and cutting chains.

- Shears and saws for slaughterhouses

- Cutting saws

- Spare Ribs Cutter machines

- Accessories (balancers, transform…)

- Spare parts